/uploadfiles/2008/6/200863011447741.jpg /uploadfiles/2008/6/200863011447741.jpg

The Italian Province of Biella has always been fertile ground for the texile field, the starting point of the best known fabrics in the world. Famas, a company specialized in the production of technical fabrics that faithfully reflect the high level of quality typical of this area, has been operating in Trivero since 1976.

There are three elements at the heart of Famas' company philosophy: Organization, Quality, Customer Service.

Around these revolves the production of the molletons and satins that are very important in the decatizing of wool cloths, an extremely delicate process which provides the finished product with dimensional stability and "hand", an undoubted advantage in terms of final quality.

/uploadfiles/2008/6/2008630114449733.jpg /uploadfiles/2008/6/2008630114449733.jpg

/uploadfiles/2008/6/2008630114554515.jpg /uploadfiles/2008/6/2008630114554515.jpg

Weaving Technology

Famas has made of textile technology, one of its points of strength by seeking continuous operative innovations that give a return in terms of final quality. To obtain a good product, it is essential to begin with high quality raw materials and support them with constant technological research. Famas can today supply a highly competitive product by taking advantage of the most advanced production systems of control and on line process. Moreover, from December 21st 1999 Famas is certified UNI EN ISO 9001:2000.

/uploadfiles/2008/6/2008630114653799.jpg /uploadfiles/2008/6/2008630114653799.jpg

Quality on Quality

The quality of a finished product is the reflected image of high - quality working process. It is the professional approach of a company. It is the final result of a fabric that is perfect throughout its length. In line with this concept, Famas dedicates commitment and competence to the control phase of its working processes, which is carried out by highly specializzed staff. Quality is checked at five different stages:

quality control of the raw material;

quality control of the yarn, verified by reference to resistence, stretch and regularity standards; during the weaving phase, the fabric is checked more and more at every shift; quality control of the grey cloth before the finishing phase; quality control of the finished cloth and verification against the standards.

/uploadfiles/2008/6/2008630114746515.jpg /uploadfiles/2008/6/2008630114746515.jpg

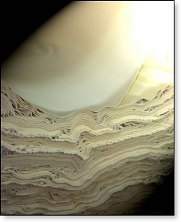

Underlying the fabric

Analysis of the factors mentioned above shows that technology and innovation have by now become essential elements underlying quality and prestige in the textile field. Precisely because of their particular consistency, the technical fabrics of Famas (including the important undercloths for decatizing) cannot undergo the mending phase commonly used for normal fabrics. And this is another reason why its products must be free from defects right from the beginning, proof of the efficiency of the adopted prevention systems. Highly specialised staff, continuous modernization and the care dedicated to its products are the pillars of the success of Famas

/uploadfiles/2008/6/2008630114832679.jpg /uploadfiles/2008/6/2008630114832679.jpg

The Right Answer for professionals of cloths

The recognition given to Famas by the textile market comes from the fact that the company can respond to every kind of question asked by people who produce an |